Time-of-Flight Secondary Ion Mass Spectrometry

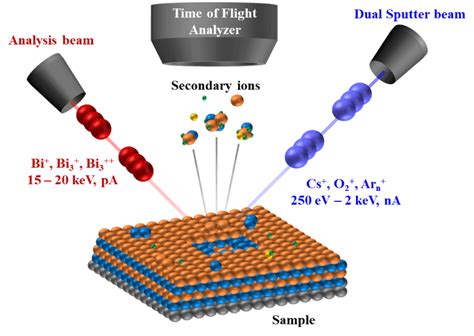

Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) is a surface analytical technique that focuses a pulsed beam of primary ions onto a sample surface, producing secondary ions in a sputtering process. Analyzing these secondary ions provides information about the molecular, inorganic and elemental species present on the surface.

For example, if there were organic contaminants such as oils adsorbed on the surface, TOF-SIMS would reveal this information, whereas other techniques may not, particularly at very low levels. Since TOF-SIMS is a survey technique, all the elements in the periodic table, including H, can generally be detected.

Moreover, this analysis can provide mass spectral information; image information in the XY dimension across a sample; and also depth profile information in the Z direction into a sample.

PRINCIPLES

Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS), also known as static SIMS, is a technique that is widely used to characterize surfaces and surface contaminants. It is closely related to dynamic SIMS, which uses a constant beam of primary ions to etch a sputter crater into a sample over a period of minutes. In contrast, TOF-SIMS uses a pulsed ion beam and does not significantly sputter etch or damage the sample surface on the timescale of the analysis. This lack of damage makes it an ideal technique for the analysis of surfaces for the presence of both elemental (most elements in the periodic table) and molecular species, with a very shallow sampling depth (1-2nm). In combination with a time of flight mass spectrometer, the technique provides excellent survey capabilities with sensitivity in the part per million (ppm) range. The primary ion beam used in TOF-SIMS instruments (typically 69Ga or 197Au) can be focused to sub-µm dimensions, meaning the technique can be used to analyze features in the 1µm to 500µm range. Both conducting and insulating samples can be analyzed successfully.

Time-of-Flight Secondary Ion Mass Spectrometry, or TOF-SIMS, works by rastering a pulsed beam of focused primary ions across the area of interest, resulting in the emission of secondary ions which are characteristic of the materials present in the top several monolayers of the sample. By accurately measuring the masses of the detected ions they can be identified and related to the chemical species present on the sample surface. The data obtained can be in the form of mass spectra, or ion images of specific species. Depth profiles can also be obtained if the technique is done in conjunction with ion sputtering (with either the same primary ion gun or using an additional Cs, O or Ar cluster ion beam).

Surface Sensitivity

The surface sensitivity of TOF-SIMS makes it a good first pass at problem solving to give an overview of what types of species are present on a sample. Other techniques can then be used to obtain additional information. TOF-SIMS is also a technique that can detect species at significantly lower levels than traditional surface analysis techniques such as XPS and Auger.

Atomic Echo Labs has been offering Time-of-Flight Secondary Ion Mass Spectrometry commercially longer than any other company, and our expertise is second to none. This is particularly crucial for TOF-SIMS, where the data sets can be extremely complex and may require more interpretation or data processing than other methods. The imaging capabilities of TOF-SIMS can provide elemental and molecular information from defects and particles on the micron scale. TOF-SIMS can also be used for depth profiling and complements dynamic SIMS. The advantages for profiling are its small areas capabilities and also its ability to do survey depth profiles without selecting specific elements of interest. More recently, cluster ion beams enable the profiling of organic materials whilst maintaining structurally significant information.

At Atomic Echo Labs, we use TOF-SIMS to assist customers with quality control, failure analysis, troubleshooting, process monitoring, and research and development. For example, the information we provide when investigating wafer surface contamination issues can help determine the specific source of the problem, such as pump oils or component outgassing, or it may indicate problems with the wafer-processing step itself (e.g. etch residue). We make sure you have person-to-person service throughout the process, so that you fully understand the test results and their implications.

Ideal Uses of TOF-SIMS

Its excellent surface sensitivity, ability to analyze organic materials and other insulators, excellent detection limits, and ability to provide elemental and molecular information makes TOF-SIMS an ideal technique for addressing the following types of applications:

- Surface analysis of organic and inorganic materials

- Surface characterization of organic and elemental materials

- Mapping the lateral distribution of surface species

- Contaminant identification (down to the ppm range for elemental or molecular species)

- Quantitative analysis of surface metals on wafers

- Failure analysis, eg: adhesion, bond pads, coatings

- Evaluation of cleaning processes (QA/QC)

- Identification of stains, discolorations, and hazes

- Examining surfaces before and after processing to identify differences

- Comparison of samples processed or stored in different environments to determine surface changes

- Imaging of elements and molecules on surfaces

- Failure and root cause analysis in case of delamination, blistering, de-wetting, staining, haze, etc.

- Survey depth profiling

Strengths

- Surface sensitive; top few monolayers

- Detection limits in the ppm range

- Survey analysis

- Survey depth profiles

- Elemental and molecular information

- Can analyze insulators and conductors

- Sub-µm spatial resolution possible in imaging mode

- Major element composition possible, in some applications

Limitations

- Absolute quantitation is difficult without extensive calibration

- Can be too surface sensitive so careful sample handling/packaging is important

- Samples must be vacuum compatible

- Datasets can be complex

TECHNIQUE COMPARISONS

Other surface analysis tools with similar depths of analysis or applications include X-ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES) and Fourier Transform Infrared Spectroscopy (FTIR). XPS provides quantitative concentrations and chemical bonding information that is not normally obtained directly using TOF-SIMS. AES can provide better spatial resolution images for elemental species, but with poorer sensitivity. FTIR can provide complementary organic information and has a greater information depth and access to commercial library spectra. This may make FTIR a better choice for identification of macroscopic amounts of material, where extreme surface information may not be of prime interest.

TOF-SIMS Technical Specifications

- Signal Detected: Elemental and molecular ions

- Elements Detected: Full periodic table coverage, plus molecular species

- Detection Limits: Fraction of a monolayer, 107 – 1010 at/cm2 (metal on semiconductor), down to 1 ppm bulk concentration in depth profiles

- Depth Resolution: 1-3 monolayers (Static mode), down to 1 nm (depth profiling)

- Information Depth: Below 1 nm (static mode), up to 10 μm (depth profiling)

- Imaging/Mapping: Yes

- Lateral Resolution/Probe Size: Down to 0.2 µm

Atomic Echo Labs has several TOF-SIMS instruments located throughout the world. Some of these instruments contain special capabilities such as large sample stages or sample cooling for the analysis of semi-volatile materials in vacuum. Our TOF-SIMS experience is unsurpassed with many of our TOF-SIMS scientists having more than 10 years of practical TOF-SIMS experience across a range of industries and applications. Historically, the California lab of Atomic Echo Labs (formerly known as Charles Evans & Associates) was directly involved in the early commercialization of TOF-SIMS instruments giving Atomic Echo Labs unmatched practical analytical experience.